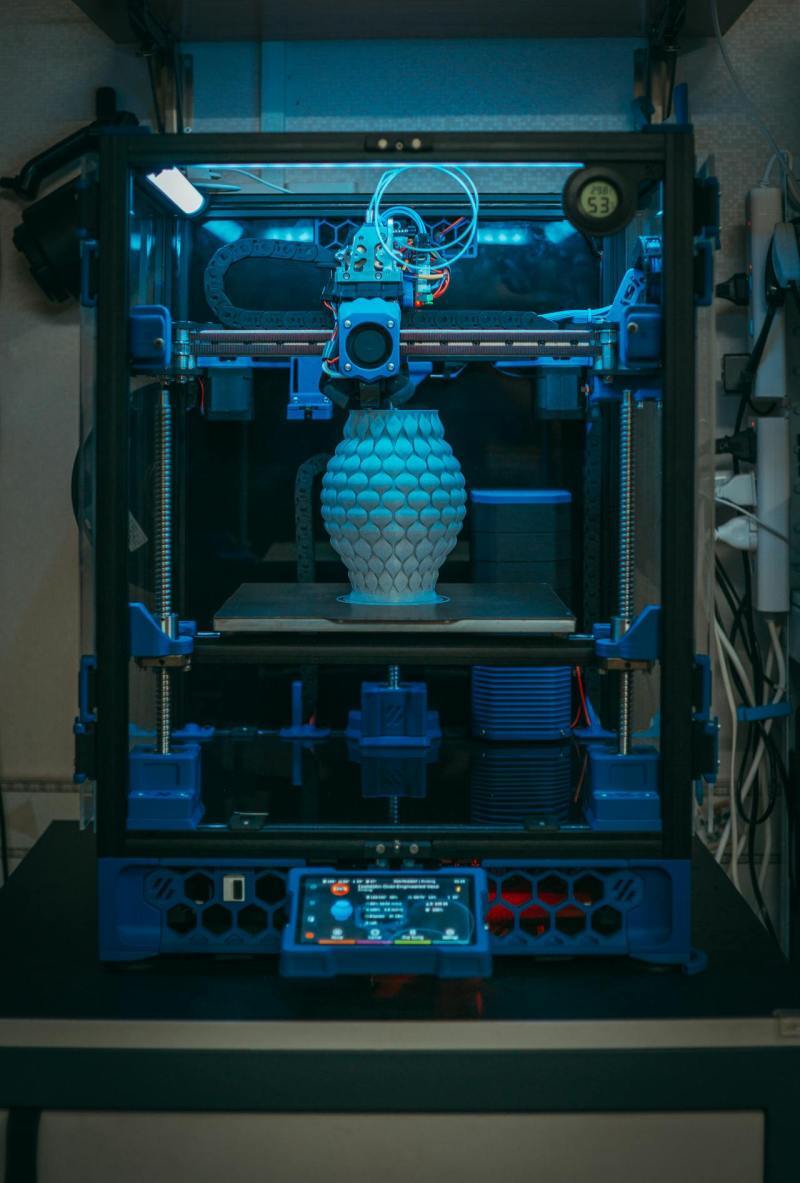

Researchers have spent years refining 3D printers to produce lightweight, natural-looking objects. Now, the right combination of silicon and modifiers can print fernlike leaves and intricate lattices.

Imagine how interior designers could make tabletops look like bark or picture frames flow like water. Fashion experts may print experimental jewelry resembling fibers and accessories that look like silky petals.

Injection Molding for Seamless Integration of Functionality and Aesthetics

Injection molding is ideal for stronger, simpler designs. The machines and molds can handle diverse materials, making a product as glossy, colorful or transparent as desired. A manufacturer could make thousands of units in a few weeks, depending on the blueprint’s details. Designers who prioritize functionality over form will still gain aesthetic benefits from this technology.

Furniture makers might craft sleek dining chairs inspired by Scandinavian aesthetics. Wearable electronics designers could impress the saturated market with products with minimalist yet practical living hinges made of thermoplastics or composites. Advanced molding methods like multi-shot molding with silicone integration are pushing the boundaries even further, allowing designers to combine different materials in a single product for enhanced visual appeal and performance.

Injection molding can also stamp a brand directly into the product, giving it a professional and luxurious look. LEGO makes some of the most famous injection-molded objects out there, which should highlight how easy it is to create durable yet visually enticing products.

3D Printing and Injection Molding for Personalized Aesthetics

Creatives must consider how the object they make evokes themselves or their customers. Therefore, customization is king. Fortunately, 3D printing and injection molding are professionals at personalization.

Game designers will want the option to make specific models and terrain for their equally imaginative customers. Print castles and mold mountains to bring fantasies to life. Households could do this on a customized gaming table with the exact dimensions for their game’s rules and comfort, achieving wondrous aesthetics for every player’s unique world.

Both technologies can also fashion a family’s dream house. Architects are making strides in 3D-printed prefabricated buildings, while injection molding can supply custom trims, shutters and vent covers to make it feel even more personalized.

Molding the Future of Design

Injection molds and 3D printing have more room to grow. Designer and creative minds everywhere should stay tuned to upcoming happenings in the industry. Materials, peripherals, production speed and shape flexibility are only a few aspects that may improve soon. The next big inspiration could be right around the corner.

The post How 3D Printing and Injection Molding Influence Product Aesthetics appeared first on Moss and Fog.