Hinna Khan’s WoolTech project reimagines electronics by asking a bold question:Could waste wool replace wiring, circuit boards, and plastics altogether?

Why wool?

Khan was inspired by farming documentaries, including Clarkson’s Farm, which highlight the staggering amount of wool that goes to waste each year in the UK. Much of this coarse wool is discarded or even burned because it’s not cost-effective to process. Meanwhile, conventional electronics depend heavily on metals, plastics, and fossil-based materials. What if that could change?

What is WoolTech?

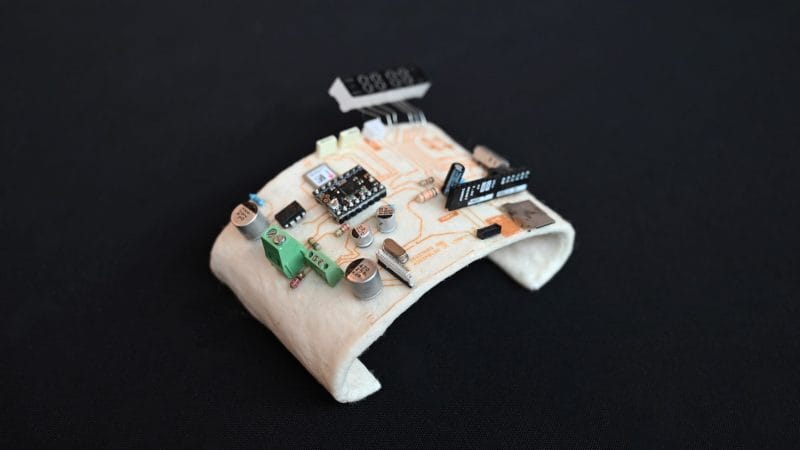

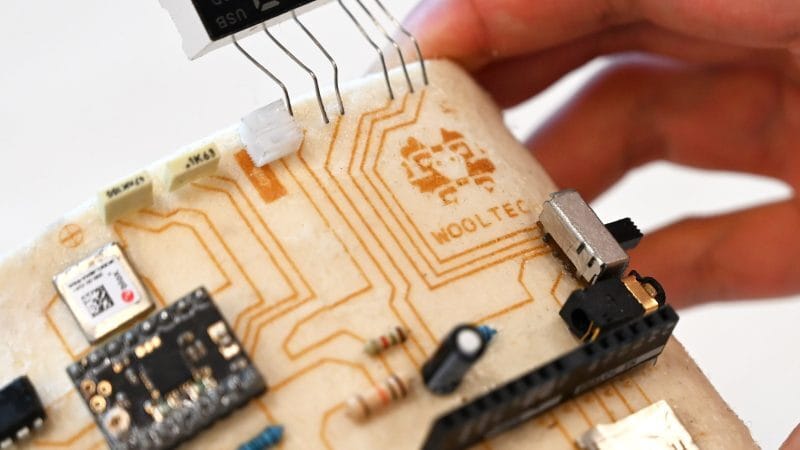

WoolTech is a biomaterial made entirely from wool, sometimes mixed with dairy-based binders. This material is used to form the entire body of an electronic product, from its housing to its circuit board and conductive pathways. The approach eliminates the need for separate components made of plastic or metal.

This prototype flashlight made of biomaterial can be made conductive by carbonizing it.

Conductivity is achieved using a laser to burn specific paths into the wool. These carbonized areas become conductive while the rest remains insulating. The process leverages wool’s high natural carbon content.

How it works and what it offers

Single-material design: The entire device, from housing to circuitry, is made from wool and is fully biodegradable

Laser-created conductive tracks: The carbon content in wool allows these tracks to carry electricity effectively

Water-soluble solder: Components can be disassembled simply by soaking them in water

Reusability: Boards can be sanded and reprogrammed multiple times before breaking down naturally in a matter of months

Lower cost: WoolTech claims its materials and processes are roughly half the cost of traditional electronics

Exploring the potential of wool

Early prototypes and lessons learned

Khan has built functional prototypes, including a flashlight and a basic circuit board. Initial experiments using conductive ink were unsuccessful due to high resistance. Laser carbonization proved to be a better solution, offering improved conductivity and eliminating the need for added materials.

What could this mean?

Reducing e-waste and agricultural waste at the same time

Less dependence on mined metals and plastics

Electronics that are easier to recycle, reuse, or compost

Rethinking how we design products, where the material becomes both the form and the function

What’s next?

WoolTech is still in the research phase but has passed early tests for durability and flame resistance. Khan is continuing development with support from Innovate UK and hopes to collaborate with labs and material partners, including Pulpatronics. The project is also in the running for the James Dyson Award and may even gain the attention of Prince Charles’s sustainability initiatives. Not bad for a recent graduate.

Images © Copyright WoolTech. Via Dezeen.

The post Could Wool Be the Future of Electronics? appeared first on Moss and Fog.